Application Guidelines

- Home page

- Application Guidelines

Usage instructions

Grid control of technical x-ray tubes

Focal spots of technical x-ray tubes of Petrick GmbH mentioned in the provided data sheets are made principally without grid control. The stated focal spot size in standard operation correspond with the technical specification. Nevertheless grid control is applicable.

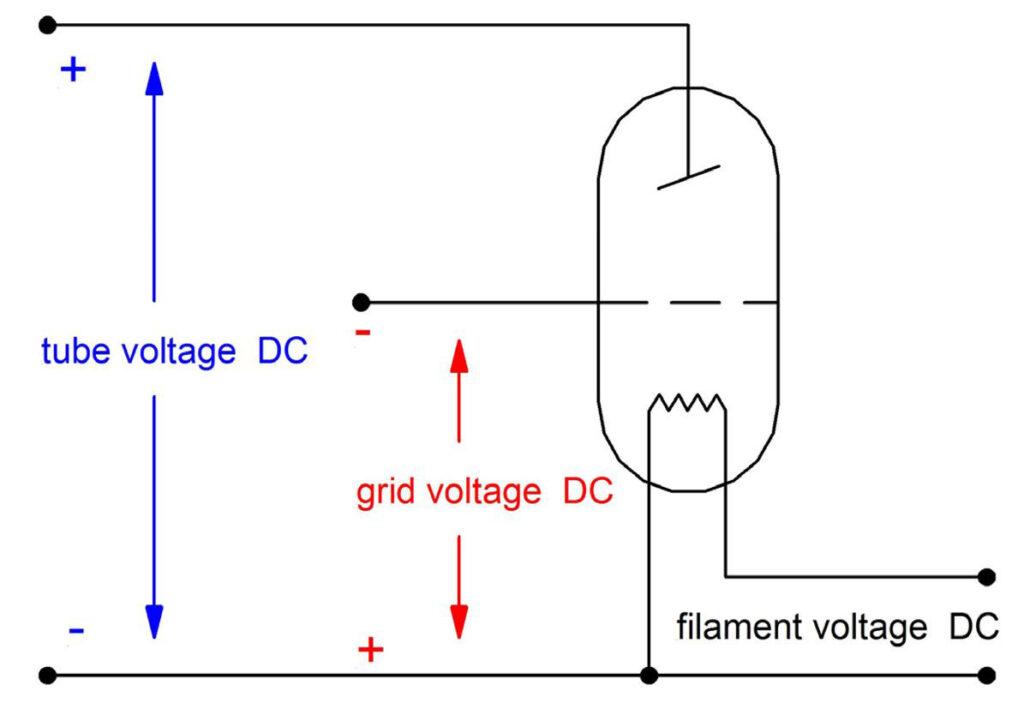

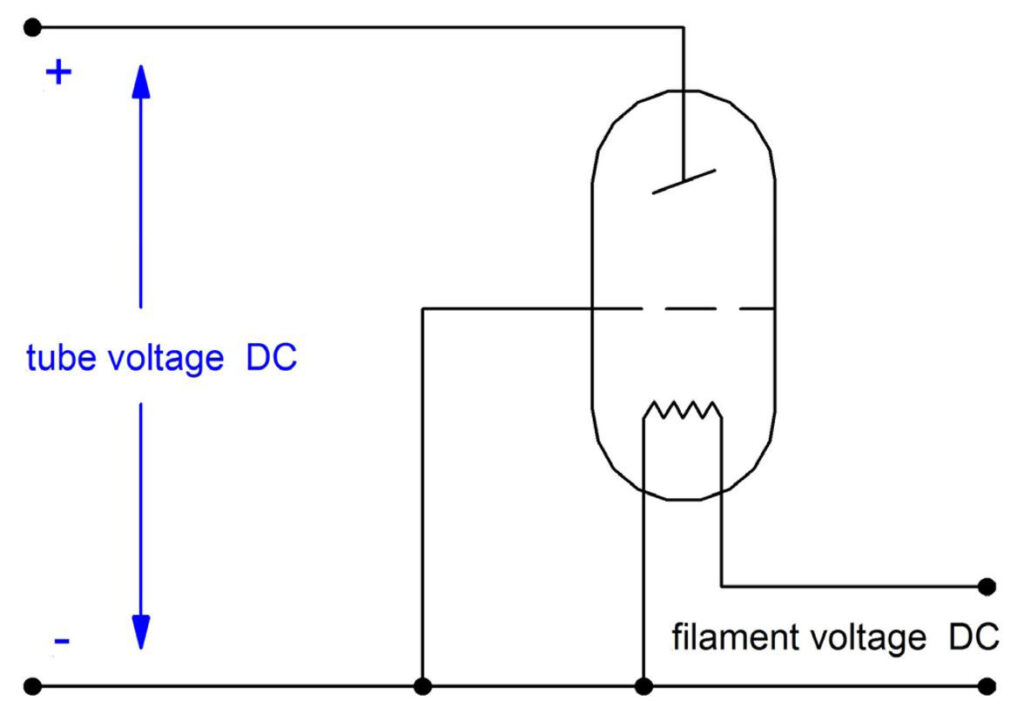

Operation with grid control

The x-ray tube can be set into standby through use of the grid control (I tube = 0 mA).

This can be realized by feeding a negative voltage between modular electrode and filament (the respective voltage depends on the x-ray tube type).

Durability

Service life of our x-ray tubes

The lifespan of an X-ray tube is limited by several possible causes of failure.

Overheating beyond normal operating temperature

This causes a minimization of the high vacuum by sublimation of target material.

Material abrasion of the filament

This follows by the release of ions from an overheated target.

Vaporization of the filament

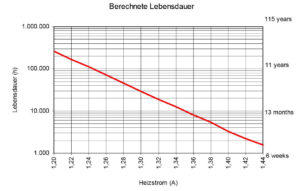

The most important limitation of the service life is the vaporization of the filament.

To reach the filament temperature necessary for an electron emission, it is heated electrically. Because of the temperature dependent natural vaporization rate of the filament material, the cross section of the filament wire becomes smaller over time, which eventually leads to filament break.

The speed of the vaporization process and the thusly to be expected service life depends directly on the filament current (diagram). The high voltage power supply connected to the x-ray source must have control circuit which secures a constant tube current. It is also important that the filament current is limitable upwards, so that overheating of the filament is precluded when turned on.

The filament current recommended for Petrick x-ray tubes are stated in the respective data sheets.

Durability

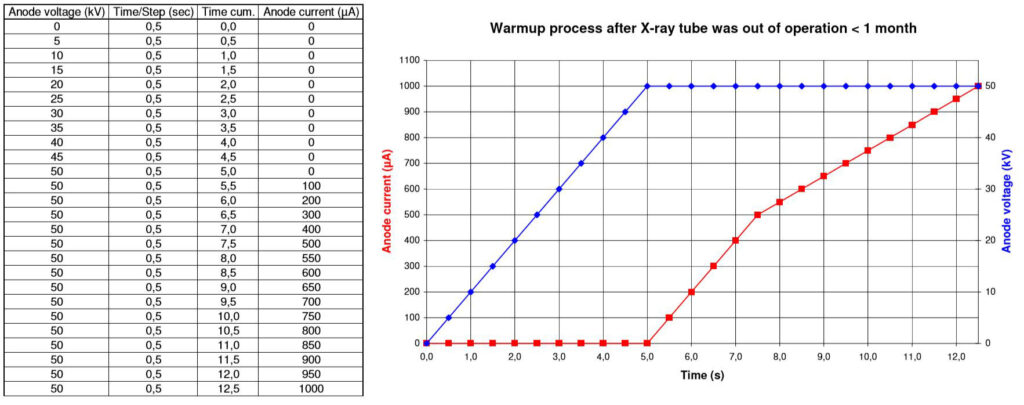

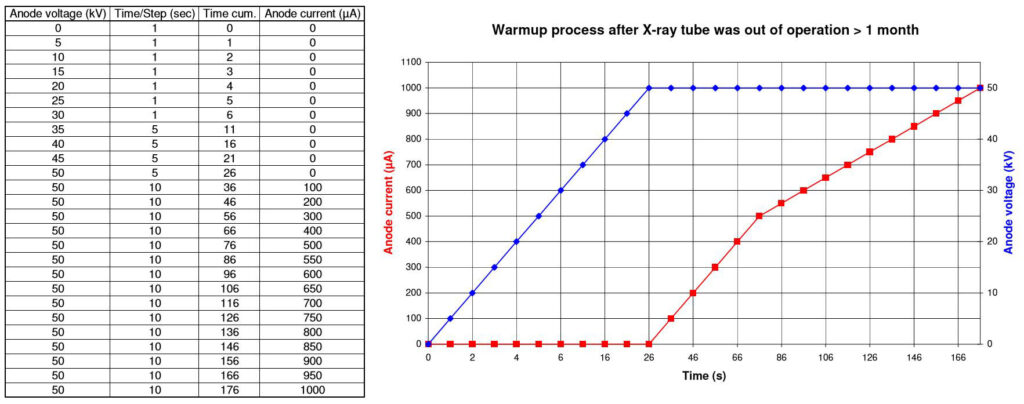

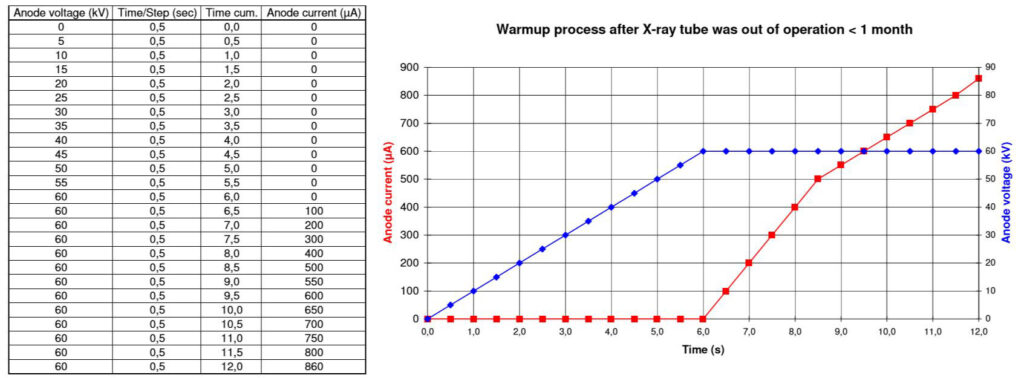

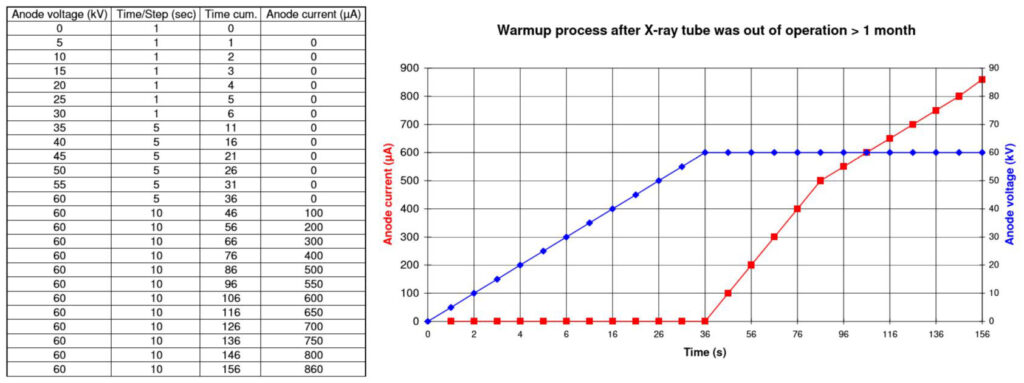

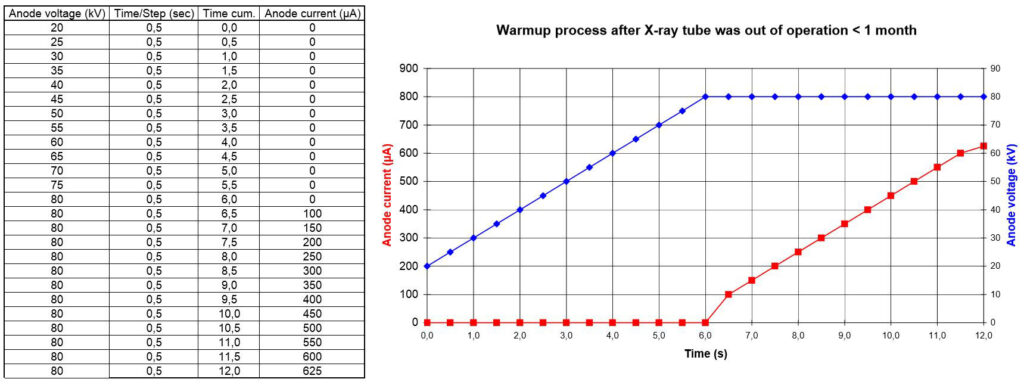

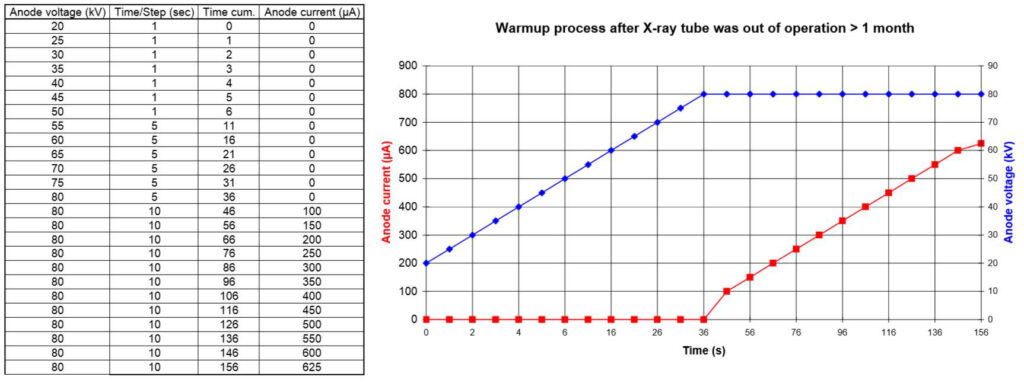

Warm up process for x-ray sources

Warm-up processes for X-ray sources are crucial not only to ensure optimal performance but also to maximize the durability of the equipment.

Do you have questions about our products?

Get in touch with us. Our contact persons will make an effort to provide feedback as soon as possible

+49 (0) 367 41 5868 0

info@petrickgmbh.de

X-ray protection

Protection against overheating of the x-ray source

A temperature switch integrated into a Petrick x-ray tube assembly protects the built-in x-ray tube against overheating. Our x-ray tube assembly systems offer a variety of different cooling methods depending on the specific application.

When using Petrick x-ray tubes without protection housing the user is responsible for a sufficient cooling.

X-ray test

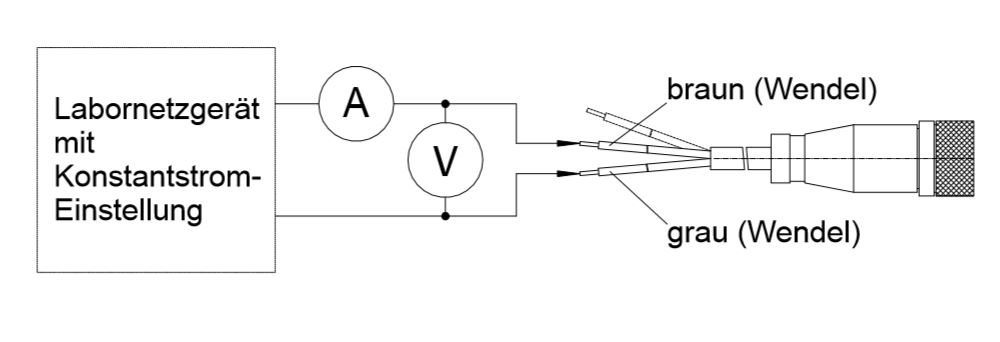

X-ray tube assembly rapid test

For goods receipt inspection, in the case of errors or failures of the x-ray tube assembly please conduct the following test. Please contact our quality management for further failure analysis.

Test

Result

x-ray tube okay

I = 1.3 A

U > 1.0 V

x-ray tube fault (vacuum loss)

I = 1.3 A

U < 1,0 V

x-ray tube fault (filament defect)

I = 0.0 A